Notched & Floded Flight

TruHelix Sectional Screw Flight Forming Machine

Company Profile:

Ding Feng Spiral Technology Co. Ltd. (Short for “DFS”) is a joint venture co-founded by Advanced Spiral Technology Pty Ltd. (Short for “AST”) in Australia and A.S.E Manufacturing Co. Ltd. in China. This is an expansion of AST’s oversea business which will mainly focus on providing professional screw conveyor design service and sectional screw flight forming solutions.

System Introduction:

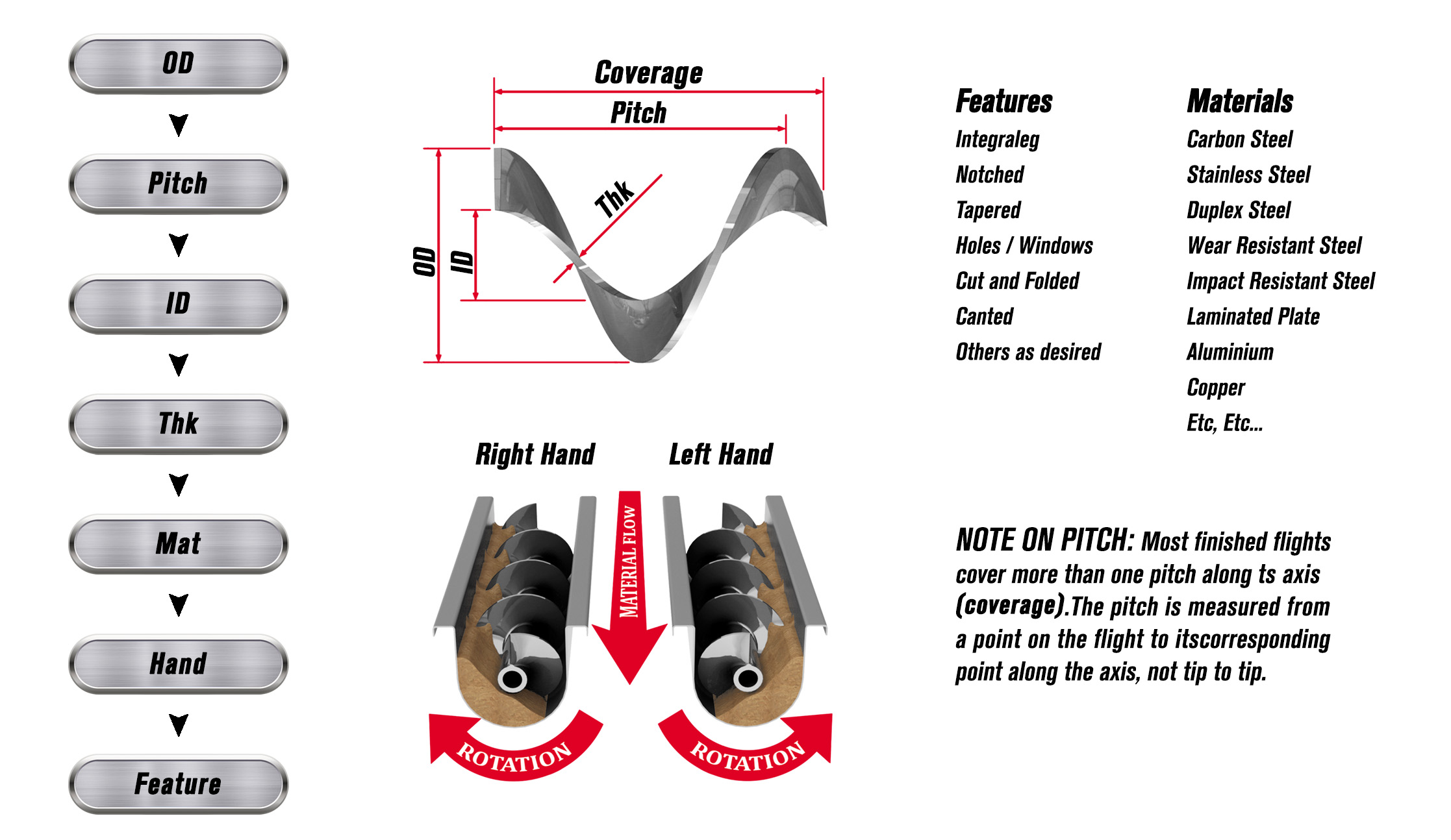

The traditional sectional flight forming process is either pulling or fixed die forming. They require a large number of dies to cover the various pitch, thickness and material. The handling and maintenance of the dies are time consuming and costly. For some particular shape of flights such as canting, it’s almost impossible for most of the manufacturers to make. The TruHelix® system not only can produce tapered ID&OD flights, canting flights but also can produce multi-step changing flights which can suit a complicated shaped inner shaft. Our system can produce flights from 150mm to 1800mm. The maximum thickness can go up to 20mm for carbon steel and 12mm for Abrasive Resistant steel. We tried to make one 1000mm diameter flight in 20mm thickness carbon steel. The forming took about 2mins. The whole process started from loading the flight blank into the machine, forming and final testing was less than 5mins.